3D Guidance®

Our quality electromagnetic tracking solution, which features ready-to-integrate components and sensors for rapid OEM product development and time to market.

3D Guidance®

Our quality electromagnetic tracking solution, which features ready-to-integrate solution components and sensors for rapid OEM product development and time to market.

Tool Navigation with Electromagnetic Tracking Technology

The 3D Guidance® electromagnetic tracking solution delivers exceptional performance and value for OEM image-guided interventional and therapy systems and medical trainers that require real-time navigation tracking capabilities.

The 3D Guidance solution tracks 6DOF sensors that can be embedded into OEM instruments such as ultrasound probes, rigid and flexible scopes, and laparoscopic tools. Continuous in-vivo tracking is maintained through difficult anatomy, even when sensors are out of sight. Low latency and fast update rates ensure the most subtle tool movements are instantly tracked and visualized within the OEM host interface.

The 3D Guidance solution is available in the driveBAY™ and trakSTAR™ configurations, as based on the Electronics Unit. The trakSTAR is a standalone desktop unit that connects to a direct power source. The smaller driveBAY fits inside the drive bay of a computer, OEM imaging cart, or medical trainer/simulator, using the host’s power supply. Both share the same tracking accuracy and reliability. The ready-to-use configuration facilitates cost-effective integration and speeds time to market.

3D Guidance Core Components

The 3D Guidance® product suite utilizes three main components consisting of the electronics unit, sensors, and transmitter. Together they allow for the most subtle of tool movements to be instantly tracked and visualized within the simulation or training interface. (Read about How Electromagnetic Tracking Works for more details.)

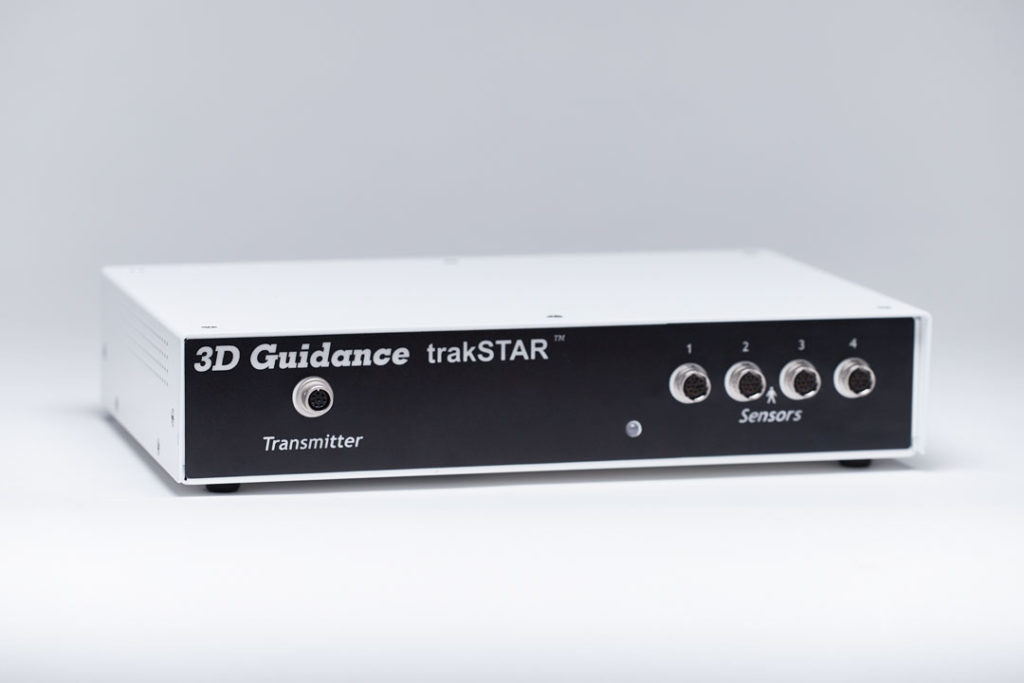

3D Guidance trakSTAR™

Calculates sensor tracking data as positions and rotational matrix and interfaces with the host application. The trakSTAR is a desktop electronics unit with an integrated power supply that can track up to four 6DOF sensors simultaneously.*

Dimensions: 290 mm x 184 mm x 64 mm

Weight: 1.31 kg

3D Guidance driveBAY™

Calculates sensor tracking data as positions and rotational matrix and interfaces with the host application. The driveBAY is an embedded electronics unit that fits into the drive bay of a PC chassis, drawing power from the host. It can track up to four 6DOF sensors simultaneously.*

Dimensions: 180 mm x 147 mm x 41 mm

Weight (enclosed format): 0.84 kg

Mid-Range or Short-Range Transmitter

Emits a low-intensity, time-varying EM field that establishes the measurement volume in combination with the sensor.

Dimensions (for MRT): 96 x 96 x 96 mm

Weight (for MRT): 2.3 kg

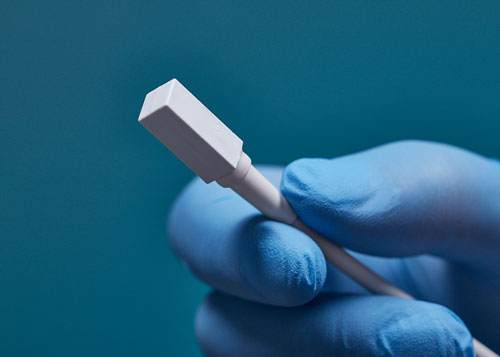

Sensors

Consists of a set of small coils in which small currents (signals) are induced when the sensor enters the EM field. The sensor acts as a localization point within the measurement volume. Sensors come fully assembled and ready-to-use; they’re wired with connectors and pre-characterized.

Number of Standard Sensors: 5 6DOF

Maximum Number of Tracked Sensors: 4 6DOF per trakSTAR unit (up to 32 sensors)

3D Guidance Technical Specifications

trakSTAR™ |

driveBAY™ |

|

|---|---|---|

| Accuracy – 6DOF Sensor | ||

| Position | 1.40 mm RMS | 1.40 mm RMS |

| Orientation | 0.50° RMS | 0.50° RMS |

| Performance | ||

| Number of Sensors | Four (4) 6DOF per unit (up to 32 sensors) | Four (4) 6DOF per unit (up to 8 sensors) |

| Measurement Rate | 80 Hz default; user-configurable from 20-255 Hz | 80 Hz default; user-configurable from 20-255 Hz |

| Dimensions & Weight | ||

| Dimensions | 290 x 184 x 64 mm | 180 x 147 x 41 mm (Fits a 5.25-inch PC drive bay) |

| Weight | 1.31 kg | 0.84 kg |

| Power & Interface | ||

| Power | 100-240 VAC, 50/60 Hz | Molex Power Connector; +12 V: 1.6A nominal, 2.9 A maximum; +5 V: 600 mA nominal |

| Interface | USB | USB |

Aurora®

Our premier electromagnetic tracking solution, which combines unrivalled measurement accuracy and expert customization for the most intricate OEM interventional applications.

Download our 12-page Education Guide to learn how you can integrate Electromagnetic Tracking Technology into your OEM medical devices to:

- Navigate instruments safely and reliably through complex anatomy.

- Target small treatment areas with

sub-millimeter accuracy and precision. - Visualize real-time position as well as orientation of an instrument.

- Track instruments even when they

are out of sight. - Embed micro sensors into flexible and

rigid instruments.

Legal Disclaimer

NDI tracking and measurement products are general metrology components that can be integrated into customer products, research experiments, and/or as components of medical devices that require precision measurement and tracking. While NDI components and technology can be integrated into original equipment manufacturer (OEM) medical devices, they are not specifically intended for a given application and, as such, have not been developed or manufactured in accordance with medical device standards. It remains the responsibility of the OEM customer or end-user to determine and test the suitability of NDI components and technology for their intended use, including performing any required ethics approval, verification, and validation required to demonstrate suitability and compliance. System-level testing, certification, and validation are the responsibility of the original equipment manufacturer or the applicable end-user and should be completed prior to the use of NDI products or technologies in any application.

*A complete 3D Guidance solution consists of an electronics unit (trakSTAR or driveBAY), transmitter, and sensors.